Industrial robotic welding automation involves the use of robotic systems to automate the process of welding in a manufacturing or production environment.

Robotic Automated Industrial Welding machines made by Nikit Engineers in India are equipped with various tools, such as welding guns, sensors, and controllers, which enable them to perform welding tasks with high precision, speed, and efficiency.

The process typically begins with the selection of the appropriate robot for the specific welding task at hand. Once selected, the machine is programmed using specialised software to perform the welding operation according to a predetermined pattern or path.

During the welding process, the robotic welding machine is guided by sensors that detect the position, orientation, and other parameters of the work-piece, allowing the robot to adjust its movements accordingly. This enables the robotic automated welding machine to accurately position the welding gun and apply the necessary heat and pressure to create a strong and consistent weld.

One of the key advantages of industrial robotic welding automation is its ability to perform repetitive tasks with high accuracy and consistency, which can lead to improved productivity, reduced labour costs, and higher quality output.

Additionally, robotic welding machine made by Nikit Engineers in India, can operate continuously for extended periods of time, without the need for breaks, leading to greater overall efficiency in the manufacturing process.

Overall, industrial robotic welding automation has become an essential tool in modern manufacturing, enabling businesses to improve their production capabilities while maintaining high standards of quality and precision.

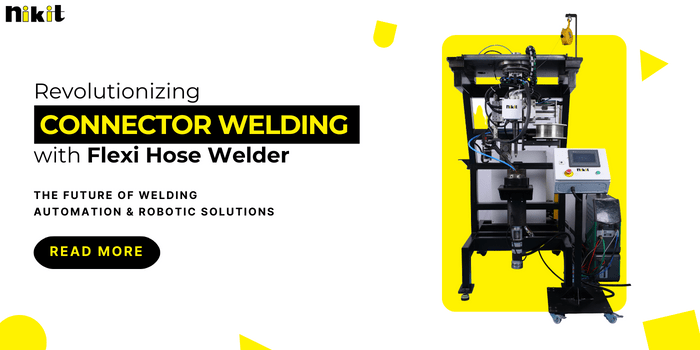

At Nikit Engineers, we pride ourselves on delivering cutting-edge welding technology tailored for stainless steel flexible hose welding. With our latest innovation—the Mini Flexi Hose Welder, we bring unparalleled precision and efficiency to the industry. Whether you manufacture flexible hoses or require a robust welding solution, this machine ensures high-quality results that meet global standards.…

Introduction Nikit Engineers has been a trailblazer in welding automation and robotic solutions, making groundbreaking advancements in industrial applications. Among their innovative achievements, the patenting of the first Cylinder Welder in 2014 marked a milestone. This pioneering invention revolutionized how hydraulic cylinders and tanks are welded, setting new benchmarks in precision, efficiency, and adaptability. The…

The transition to clean energy is crucial, and while much attention is given to the power and transportation sectors, the industrial sector remains a significant challenge. Responsible for about a quarter of the U.S.’s greenhouse gas emissions, the industrial sector’s heavy reliance on fossil fuels for heat generation necessitates innovative solutions. Enter Nikit Engineer’s Thermal…

When it comes to fabricating flexible hoses, particularly in industries that demand high standards of cleanliness and durability, the welding process is of paramount importance. One critical aspect that often determines the quality of these hoses is purging. In this blog, we will explore the significance of Purging in Achieving Well Qualified Flexible Hose Welding,…

We are excited to announce that Nikit Engineers has partnered with Sashma Group to bring our advanced welding and robotic solutions to the Middle East, Kazakhstan, and Singapore. This strategic collaboration will market, sell, and install our cutting-edge technology, marking a new era of growth and innovation for both companies. A Strong Partnership for Growth…

At Nikit Engineers Welding Automation and Robotics Solutions, we are proud to introduce our revolutionary Flexi Hose Welder. This cutting-edge technology is setting new standards in connector welding for stainless steel flexible hoses. Gone are the days of traditional welding methods that compromise quality and efficiency. Our Flexi Hose Welder utilizes state-of-the-art technology to ensure…

Elevating Precision and Throughput in Semiconductor Welding Processes In the intricate world of semiconductor manufacturing, precision and efficiency are paramount. Every component, every process, must adhere to stringent standards to ensure optimal performance and reliability. Among the myriad challenges faced in this industry, welding flexible metallic hoses stands out as a particularly complex task, demanding…

In the heart of Kolkata, amid the bustling atmosphere of industrial innovation, Nikit Engineers made waves at the WELDTECH EXPO 2024. From March 15th to March 19th, 2024, the city witnessed the unveiling of cutting-edge welding technology that promises to redefine industry standards. At Stall no. B15, Nikit Engineers proudly showcased our Mini Profile Welder,…

In the dynamic landscape of industrial fabrication, the quest for efficiency, precision, and cost-effectiveness has led to significant advancements. Among these, pipe spool fabrication stands out as a vital process in industries ranging from oil and gas to pharmaceuticals and beyond. At the forefront of this evolution is Nikit Engineers Welding Automation and Robotic Solutions,…

In the realm of industrial automation, precision and efficiency are paramount. Nikit Engineers Welding Automation and Robotics Solutions India have been at the forefront of revolutionizing industrial processes with their cutting-edge technologies. Among their impressive array of offerings, the Mini Profile Welder stands out as a versatile solution for welding various industrial components with utmost…