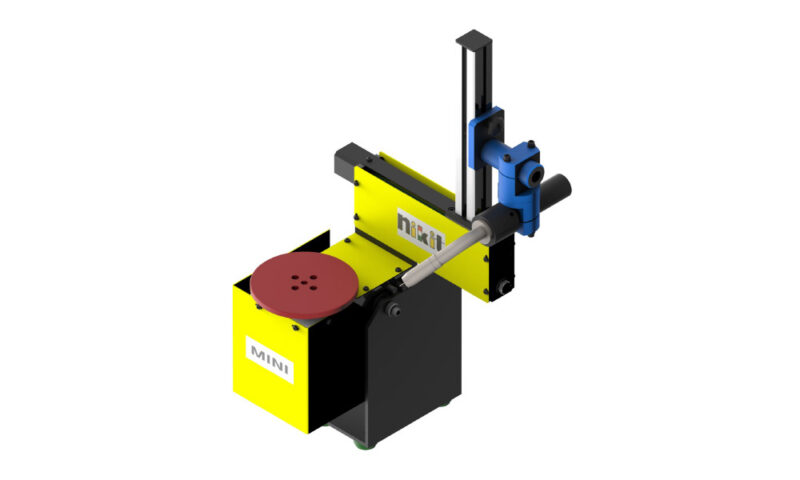

Our mini circular welders are developed exclusively for rotary components ranging from 10mm to 200mm diameters catering to both GMAW & GTAW weld methods with manual height adjustment systems for up to 50mm range, torch dual axis rotary angle markers and a basic mode data logger combine to give a better user experience for a professional weld.

Thank you for reading this post, don't forget to subscribe!

The system is highly energy efficient with less than 200W consumption and ready to use out of the box module, we in-tend to give the best automation solution in a smaller package.