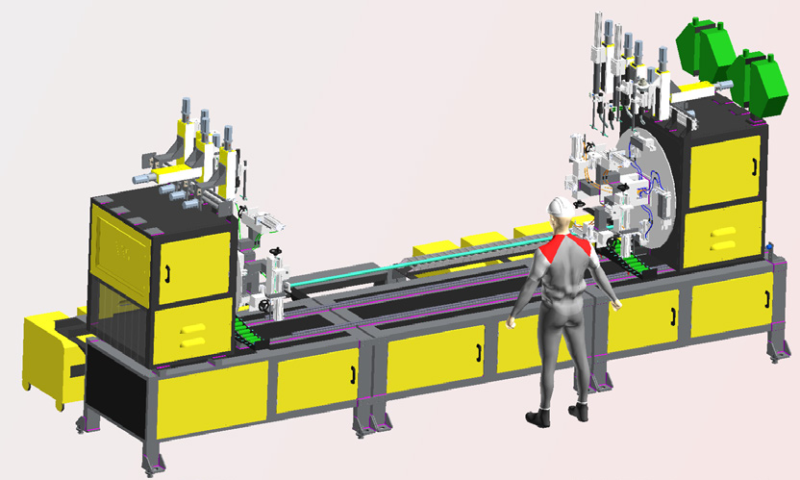

As one of the pioneers in welding solutons we have successfully designed and developed a mult stage tandem beam welding soluton that caters to the racking industry, constructon industry and whole lot of other similar applicatons.

Thank you for reading this post, don't forget to subscribe!

From a beam length of 500mm to 5000mm & profiles of 40mm to 200mm the system addresses highest number of variables in components for welding. Our fourstageparallelloading,unloading&weldingprocess contributes to the lowest amount of tme required to weld any standard beams. For example a 40mm * 60mm beam gets produced within 22 seconds, this is practcally tested and currently in use in one of the leading racking industry.