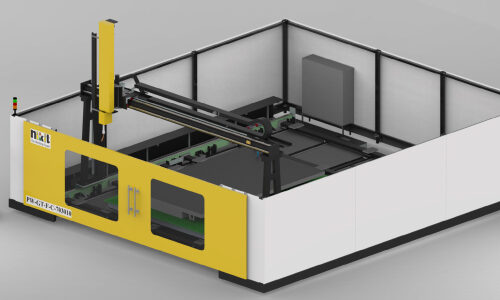

Our profile welders are developed for applications ranging from frames ,panel box, weighing scale , stands and similar range of welding requirements by both GMAW and GTAW methods.

Thank you for reading this post, don't forget to subscribe!

With the system highly power efficient and our innate focus on intelligentized welding manufacturing (IWM) process, we have developed our system to be less operator dependent and ingeniously welder much smarter.