Nikit Engineers’ Weld Process System (WPS): A Quarter of Excellence in Welding Across Diverse Industries

Report for the Third Quarter of 2023 (Week 26 to Week 39)

Welding is a fundamental process in the manufacturing and assembly of various industrial components across different sectors. In the third quarter of 2023 of our Weld Process System, Nikit Engineers undertook an extensive range of welding projects spanning a multitude of industries, reinforcing their reputation as leaders in the field of welding. This report provides an overview of the diverse components and industries where Nikit Engineers Welding Automation & Robotics Solutions India showcased their expertise during this period.

Thank you for reading this post, don't forget to subscribe!Muffler Bracket Welding – Infrastructure Industry

One of the notable projects undertaken by Nikit Engineers involved the welding of muffler brackets for the infrastructure industry. The Circular Welding process was employed to ensure precision and durability in the brackets used in heavy machinery such as excavators.

Boom Pipe End Fitting Welding – Infrastructure Industry

Nikit Engineers also demonstrated their welding prowess in the infrastructure sector by welding boom pipe end fittings. This process is critical for the structural integrity of equipment used in construction and infrastructure development.

Bellow Assembly Plate Welding – Oil and Gas Industry

The oil and gas industry demands the highest standards of welding, and Nikit Engineers delivered with precision in welding bellow assembly plates, vital components for maintaining the integrity of pipelines and equipment in this sector.

Connector & Tube Welding – Automotive Industry

In the automotive industry, where safety and reliability are paramount, Nikit Engineers showcased their expertise by welding connectors and tubes. These components are crucial for fluid systems within vehicles.

Stainless Steel Flange to Tube Welding – Pharmaceutical Industry

Meeting stringent quality requirements, Nikit Engineers skilfully executed stainless steel flange to tube welding for the pharmaceutical industry. Such precision is vital to maintaining hygiene and product integrity in pharmaceutical processes.

Aluminium IP Rated Electric Panel Box Welding – Electrical Industry

The electrical industry relies on precise welding for various components, including IP-rated electric panel boxes. Nikit Engineers ensured the durability and safety of these crucial components through their welding expertise.

Flexible Hose Welding – Micro-conductor Industry

In the microconductor industry, flexibility and precision are key. Nikit Engineers’ welding capabilities were on full display as they expertly welded flexible hoses used in delicate microconductor applications.

Case to Socket Welding – Pressure Gauge Vessel and Oil and Gas Industry

In another venture within the oil and gas sector, Nikit Engineers excelled in case-to-socket welding for pressure gauge vessels. This demonstrates their commitment to maintaining the safety and reliability of critical equipment.

Thermal Battery Welding for Defence Launch Missiles – Defence Industry

The defence industry demands the utmost precision and reliability. Nikit Engineers proved their mettle by delivering exceptional thermal battery welding services for missile launch systems.

Nut Tack Welding of Automobile Components – Automotive Industry

Nikit Engineers contributed to the automotive industry by executing nut tack welding for various automobile components. This process is vital for the structural integrity and safety of vehicles.

Rocker Body with Pin Tig Fusion Tack Welding – EV Industry

As the electric vehicle (EV) industry surges forward, Nikit Engineers played a pivotal role in ensuring the quality of EV central locking assembly through expert rocker body with pin Tig fusion tack welding.

Face Welding of Flange & Shaft with MIG Welding – Infrastructure Industry

Another significant project in the infrastructure sector was the face welding of flanges and shafts using MIG welding. This process ensures the structural integrity of heavy machinery components.

X-ray Machines Cathode and Anode Assembly Welding – Medical Industry

In the medical industry, precision is non-negotiable. Nikit Engineers demonstrated their commitment to quality by expertly welding cathode and anode assemblies for X-ray machines.

Port Welding Fluid Transfer Unit for Injection Molding Machines – Injection Molding Industry

Nikit Engineers also showcased their versatility by welding fluid transfer units for injection molding machines. This demonstrates their ability to cater to diverse industrial needs.

Pressure Vessels Welding

The oil and gas sector relies heavily on pressure vessels, and Nikit Engineers showcased their expertise in welding these critical components to exacting standards.

Stainless Steel and Mild Steel Tanks

The food and pharmaceutical industries, among others, demand impeccable welds for their storage tanks. Nikit Engineers ensured the highest quality welds on both stainless steel and mild steel tanks.

Fluid Transfer Unit for Injection Moulding Machines

Precision is paramount in injection molding. Nikit Engineers successfully contributed to the production of fluid transfer units, ensuring flawless welds that enhance the efficiency of these machines.

Stellite Welding

Often used in extreme environments, Stellite welding is a challenging task. Nikit Engineers exhibited their prowess in working with this specialized material.

Foot Rest Welding

In the automotive sector, footrests are crucial for safety and comfort. Nikit Engineers’ precise welding ensures the integrity of these components.

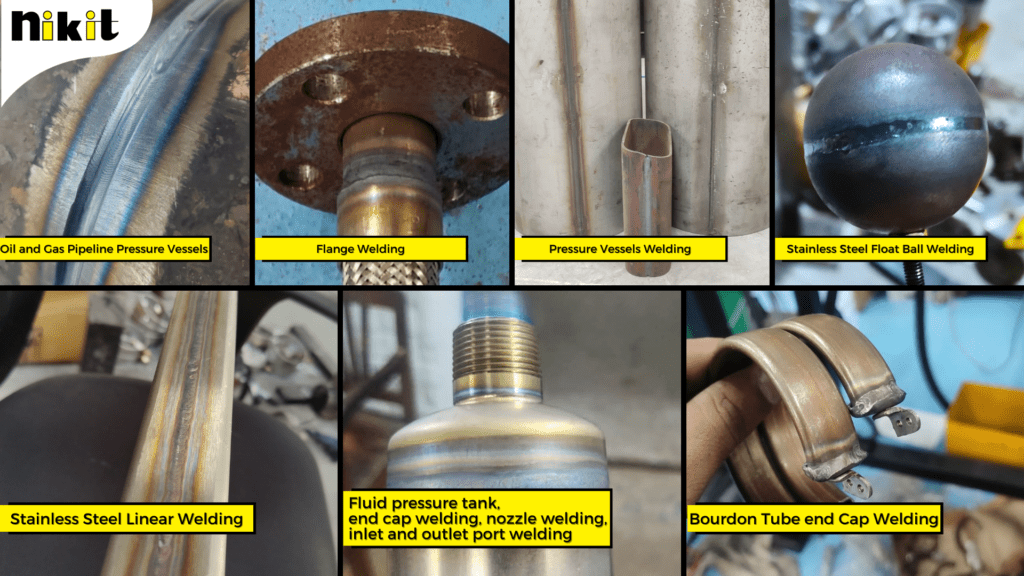

Oil and Gas Pipeline Pressure Vessels

With the growing demands of the energy sector, Nikit Engineers played a vital role in welding pressure vessels that are pivotal to oil and gas pipelines’ safe operation.

Stainless Steel Float Ball Welding

The chemical industry relies on precise float ball welding to maintain consistent fluid levels. Nikit Engineers met this requirement with precision.

Flange Welding

Flanges are ubiquitous in various industries, and Nikit Engineers consistently delivered reliable and durable flange welds.

Stainless Steel Linear Welding

Precision linear welding is essential in industries where hygienic conditions are paramount. Nikit Engineers excelled in this aspect.

Front Crash Guard

Ensuring vehicle safety, front crash guards require robust welding. Nikit Engineers contributed to the safety of automotive users with their welding expertise.

3-Wheeler EV Base Frame Welding

In the era of electric vehicles, the EV base frame welding by Nikit Engineers played a role in shaping the future of transportation.

End Cap Welding of Fluid Transfer

Besides fluid transfer units, Nikit Engineers also delivered precise end cap welds, ensuring leak-free performance.

Bourdon Tube End Cap Welding

Accuracy in Bourdon tube end cap welding is vital for pressure measurement instruments. Nikit Engineers demonstrated their commitment to precision.

Fluid Pressure Tank End Cap, Nozzle, Inlet, and Outlet Port Welding

These components are integral to various industries, and Nikit Engineers’ welding prowess ensured their reliability.

The Nikit Engineers Difference: Free Weld Trial Process

What sets Nikit Engineers apart is their commitment to quality and innovation, exemplified by their Free Weld Trial Process. This process allows clients to experience the exceptional quality of Nikit Engineers’ welding services before committing to a project.

By offering free weld trials, Nikit Engineers provide a tangible demonstration of their welding capabilities, helping clients make informed decisions. This approach not only builds trust but also underscores their commitment to delivering exceptional results.

At, Nikit Engineers Welding Automation & Robotics Solutions India our commitment to precision, quality, and safety is evident across these diverse welding projects. Our Free Weld Trial Process continues to set a benchmark in the welding industry, providing clients with the assurance of excellence in every weld. As we navigate various industries with our expertise, we reinforce our position as leaders in the welding industry, driven by a dedication to craftsmanship and reliability.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineers