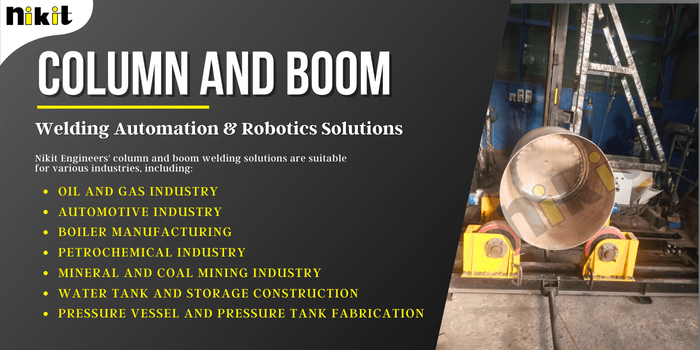

Enhanced Column and Boom Welding Solutions by Nikit Engineers

Nikit Engineers column and boom welding solutions are manufactured to meet industry standards, ensuring exceptional performance whether you require heavy-duty or light-duty equipment. We are renowned for providing top-notch products and services in the field.

Thank you for reading this post, don't forget to subscribe!Key Features of Our Column and Boom Welding Solutions

We offer comprehensive technical consulting services to support you throughout the process.

- Comprehensive technical consulting services available full-time.

- Competitive pricing with a one-year quality warranty.

- Customizable components to meet your specific requirements.

- Collaboration with renowned international brands.

Optimize Your Welding Process with Column and Boom Welding Automation

Column and boom welding automation machines are designed to streamline your operations, reducing labor-intensive tasks and improving efficiency. These machines excel in tackling challenging welding conditions that cannot be easily accomplished manually.

The welding head is positioned at the end of the boom, allowing it to be lifted and retracted to achieve the desired welding position. We offer various column and boom sizes, such as 3×3, 55, and 8×8, to cater to different workpiece diameters and lengths.

Why Choose Nikit Engineers for Column and Boom Welding?

Our commitment to delivering high-quality standards stems from the following factors:

- Rigorous inspection and review of the production process.

- Tempering and stress relief of all steel structures.

- Adherence to industry standards in production requirements.

- Utilization of premium-grade accessories and electrical parts.

When Do You Need a Column and Boom Welding Solution?

Automatic welding systems are designed to be mounted on sturdy structures, enabling them to move seamlessly from one seam to another, providing unmatched accuracy and consistent repeatability compared to manual methods. True automatic welding requires the use of a manipulating device that brings the welding head to the workpiece.

Tailor Your Column and Boom Welding Solution

We offer customizable options to tailor your column and boom welding system to your specific needs:

- Control platform options include joystick or fully integrated touchscreen interfaces.

- Choose from SAW or GMAW welding systems, including single, twin, or tandem wire options.

- Explore Cold Wire TIG Systems.

- Opt for powered cross slides with 1 or 2 axes.

- Enhance your setup with weld camera systems for SAW or Open Arc welding.

- Select the travel car type, whether powered or manual.

- Incorporate a pre-heating system with a rolling induction heater.

- Integrate flux recovery and delivery systems, including dual SAW or MIG/SAW setups.

Experience the Benefits of Welding Automation with Column and Boom

Welding automation involves integrating various welding machines into your operations to boost productivity, accuracy, and speed. Column and boom welding systems play a crucial role in improving overall welding processes and offer numerous advantages, including:

a. Mobility: Manual manipulators feature built-in swivel casters for fast movement, while mechanized options can be both manually and computer-operated, allowing easy switching between workstations.

b. Safe working environment: Adjustable features and safety straps ensure the weld head can be moved closer or farther from the workpiece, minimizing heat exposure. Safety bumpers keep the gun, boom, and manipulator secure during welding..

c. Flexibility and versatility: Column and boom welding systems seamlessly integrate with other welding equipment, enabling access to difficult locations and the performance of complex welding tasks.

d. Improved quality:Welding accuracy is significantly enhanced with column and boom systems, enabling precise operations in challenging spots that are hard to reach manually. Repetitive operations can be easily adjusted, leading to consistent quality.

e. Increased productivity:By eliminating the need for frequent adjustments, column and boom systems enhance production efficiency, saving time and resources in continuous welding operations.

f. Enhanced user experience: Welders can work more effectively and focus on technical aspects while column and boom handle heavy lifting and accessibility, resulting in a better overall experience.

g. Reduced floor space: Column and boom systems occupy less floor area compared to traditional lifting equipment, providing a more compact and safer solution.

h. Reduced welding costs: With improved accuracy and reduced chances of failure, column and boom systems minimize welding costs, making them a cost-effective investment.

Expand Your Applications with Column and Boom Welding

Our column and boom welding machines find applications across various industries, including:

- Pressure vessels and pressure tanks

- Boilers

- Water tanks and storage

- Automotive industry

- Petrochemical industry

- Mineral and coal mining industry

- Oil and gas industry

Common Welding Operations Supported

Our column and boom welding machines are compatible with a wide range of welding operations, including:

- Submerged Arc Welding (SAW)

- Gas Tungsten Arc Welding (GTAW) or TIG Welding

- Gas Metal Arc Welding (GMAW) or MIG Welding

- Flux-Cored Arc Welding (FCAW)

- Plasma Arc Welding (PAW)

Partner with Nikit Engineers for Reliable Welding Automation Solutions

Count on Nikit Engineers to provide reliable column and boom welding solutions that optimize your welding processes and deliver superior results. Contact us today to discuss your requirements and benefit from our expertise in welding automation and robotic solutions.

At Nikit Engineers, we understand that each application is unique, and we work closely with our customers to develop customised welding solutions that meet their specific needs. We use the latest technology and equipment to ensure that our welding solutions are efficient, reliable, and cost-effective. We also offer training and support services to ensure that each welding process works efficiently.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineers