Revolutionising Welding Processes: Solutions for Welding Stainless Steel Pressure Vessels, Storage Tanks, and Silos

Discover how Nikit Engineers’ cutting-edge Robotic Welding Automation systems are transforming the welding industry. From groove root and fill-up welding to Boom and column welding, explore the versatility, precision, and efficiency of these advanced systems, Solutions for Welding Stainless Steel Pressure Vessels Storage Tanks and Silos

Thank you for reading this post, don't forget to subscribe!In the realm of industrial automation, welding plays a vital role in fabrication and assembly processes. To meet the increasing demands for efficiency, precision, and productivity, Nikit Engineers has introduced cutting-edge Robotic Welding Automation systems. These systems are specifically designed to excel in various welding applications, including groove root and fill-up welding, Boom and column welding, and rotary groove welding. By leveraging the latest technology, Nikit Engineers aims to transform the welding industry.

Groove Root and Fill-Up Welding:

Nikit Engineers Robotic Welding Automation system excels in groove root and fill-up welding, offering seamless handling of plate thicknesses ranging from 6mm to 8mm. This versatility makes it suitable for a wide range of applications. With stainless steel (SS) as the primary material, the system ensures robustness and longevity of the welds. Additionally, the system’s groove size, measuring 6mm and 8mm in width and 5.5mm in depth, enables precise and strong connections.

Boom and Column Welding:

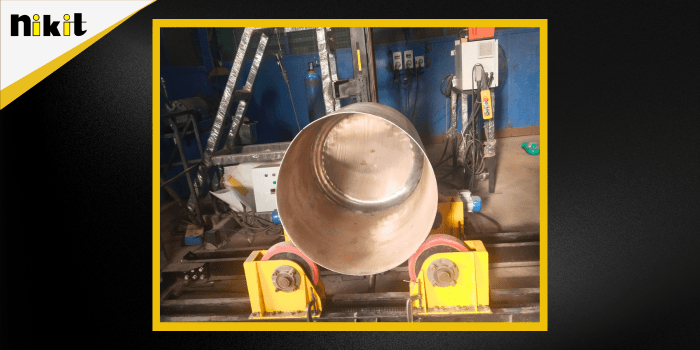

In addition to groove root and fill-up welding, Nikit Engineers’ automation system demonstrates exceptional performance in Boom and column welding. This capability is crucial for constructing structural components like beams and columns across various industries. With its remarkable versatility, the system can handle different component diameters, accommodating a maximum diameter of 800mm. By automating Boom and column welding processes efficiently, Nikit Engineers’ system significantly reduces production time while enhancing overall welding quality.

Robotic Welding Parameters:

Nikit Engineers’ Robotic Welding Automation system incorporates adjustable parameters to ensure optimal performance based on specific requirements. The system’s welding time of 5.3 minutes showcases its high-speed capabilities. Achieving SPM (strokes per minute) welding, the system maintains consistent weld quality and minimizes production time.

Machine No: Gl499-Spm Boom and Column Weld:

Nikit Engineers Gl499-Spm Boom and Column Weld machine stands out in the robotic welding industry. Specifically designed for rotary groove welding, it utilizes the Tungsten Inert Gas (TIG) welding process to achieve excellent weld integrity. This machine is optimized for stainless steel (SS) components, ensuring high-quality welds with minimal distortion. With a sheet thickness of 8mm and a component diameter of 600mm, it proves to be a versatile solution applicable to a wide range of manufacturing needs.

Weaving Technique and Production Time:

The Gl499-Spm Boom and Column Weld machine incorporates weaving techniques that enhance both weld strength and aesthetics. With a weaving width of 10mm and a weaving speed of 120, it creates uniform and robust weld joints. Impressively, the total production time for this machine is only 15 minutes, making it an exceedingly efficient solution for high-volume manufacturing.

Concluding – Solutions for Welding Stainless Steel Pressure Vessels Storage Tanks and Silos

Nikit Engineers’ Robotic Welding Automation systems provide a game-changing solution for various welding applications, including groove root and fill-up welding, Boom and column welding, and rotary groove welding. These systems offer unparalleled precision and productivity by accommodating different plate thicknesses, component diameters, and groove sizes. By optimizing parameters such as weld time, weaving technique, and production time, Nikit Engineers has created a comprehensive solution that meets the demands of modern industrial welding. As the manufacturing industry continues to evolve, Nikit Engineers’ Robotic Welding Automation systems pave the way for faster, more efficient, and higher-quality welding processes. Embrace the future of welding with Nikit Engineers.

Why Choose Nikit Engineers Robotic Welding Automation Solutions for Welding Stainless Steel Pressure Vessels Storage Tanks and Silos?

With our exceptional expertise, cutting-edge technology, and commitment to customer satisfaction, Nikit Engineers stands out as the ideal choice for all your robotic welding automation requirements. Here are some compelling reasons why you should consider partnering with Nikit Engineers:

- Extensive Industry Experience: Nikit Engineers boasts a rich history of serving clients across various industries with their robotic welding automation solutions. With years of experience under their belt, they possess a deep understanding of the unique challenges and requirements faced by different sectors. This expertise enables them to develop tailor-made solutions that address specific industry needs effectively.

- Technological Excellence: Nikit Engineers stays at the forefront of technological advancements in robotic welding automation. They invest heavily in research and development to stay updated with the latest innovations. By leveraging state-of-the-art equipment, software, and tools, they deliver cutting-edge solutions that optimize efficiency, productivity, and precision in your welding processes.

- Customised Solutions: Every business has its own distinct set of requirements when it comes to robotic welding automation. Nikit Engineers recognizes this fact and places great emphasis on developing customized solutions. They take the time to understand your unique needs, workflow, and production goals, and design solutions that seamlessly integrate into your existing setup. Their ability to provide tailored solutions ensures maximum efficiency and a perfect fit for your business.

- Comprehensive Service Offerings: Nikit Engineers offers a wide range of services to cater to all aspects of robotic welding automation. From concept design and system integration to installation, training, and after-sales support, they provide end-to-end solutions. Their comprehensive approach ensures a smooth transition to automated welding processes and ongoing assistance to maintain optimal system performance.

- Skilled and Dedicated Team: At the core of Nikit Engineers’ success is their team of highly skilled professionals. They comprise experienced engineers, technicians, and support staff who possess in-depth knowledge of robotic welding automation. With their expertise and dedication, they work closely with clients, offering guidance and support throughout the project lifecycle. Their commitment to excellence guarantees the successful implementation of your automation solution.

- Emphasis on Quality and Reliability: Nikit Engineers places utmost importance on delivering high-quality, reliable solutions to their clients. They adhere to stringent quality control measures at every stage of the project. By utilizing top-grade components and following industry best practices, they ensure that their automation systems perform optimally, reduce downtime, and contribute to long-term cost savings.

- Customer-Centric Approach: Customer satisfaction lies at the heart of Nikit Engineers’ business philosophy. They prioritize building strong and lasting relationships with their clients, which is evident in their exceptional customer service. From the initial consultation to ongoing support, they provide clear communication, prompt response times, and a proactive approach to addressing any concerns or queries.

If you are seeking a trusted partner for your robotic welding automation needs, Nikit Engineers offers a compelling package. With their industry experience, technological prowess, customised solutions, comprehensive services, skilled team, focus on quality, and customer-centric approach, they are well-equipped to meet and exceed your expectations. Choose Nikit Engineers and experience the benefits of efficient, precise, and reliable robotic welding automation in your business.

At, Nikit Engineers Robotic Welding Automation Solutions, we are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineers