In the world of welding automation and robotics solutions, it’s crucial to understand the different types of orbital welding processes available and how they can benefit your welding services. In this blog, we’ll delve into various forms of orbital welding techniques without getting lost in marketing jargon. Our aim is to provide you with factual information to help you make informed decisions for your welding projects.

Thank you for reading this post, don't forget to subscribe!TIG Orbital Welding:

Tungsten Inert Gas (TIG) orbital welding is known for its precision and clean results. It’s commonly used in industries where the weld quality must meet the highest standards, such as aerospace and pharmaceuticals. TIG orbital welding ensures a controlled arc, minimal heat input, and superior weld integrity.

MIG Orbital Welding:

Metal Inert Gas (MIG) orbital welding is all about efficiency and speed. It’s frequently employed in high-production environments, like automotive manufacturing. MIG welding uses a consumable electrode and an inert gas to protect the weld pool, making it ideal for joining thicker materials quickly.

Plasma Orbital Welding:

Plasma orbital welding offers the advantage of extremely high temperatures, making it suitable for welding exotic materials such as titanium and superalloys. It produces precise, clean welds with minimal distortion.

Gas Metal Arc Welding (GMAW):

GMAW, also known as MIG welding, is versatile and widely used. It’s perfect for a variety of materials and applications. GMAW orbital welding is appreciated for its adaptability and ease of automation.

Flux Core Arc Welding (FCAW):

Flux core arc welding is a preferred choice for outdoor welding applications, thanks to its ability to handle windy conditions. It utilizes a tubular wire filled with flux to protect the weld pool from environmental factors.

Gas Tungsten Arc Welding (GTAW):

Gas Tungsten Arc Welding, or TIG welding, is the go-to choice for precise, high-quality welds. It excels in applications where weld appearance and quality are paramount.

Submerged Arc Welding (SAW):

Submerged arc welding is commonly used for welding thick materials. It involves a granular flux that covers the weld, reducing the risk of spatter and ensuring a solid, reliable weld.

Laser Beam Arc Welding:

Laser beam arc welding is a cutting-edge technology that utilises a laser to create the weld. It’s highly precise and can be used for a variety of materials. Its speed and accuracy make it a valuable tool in modern welding automation.

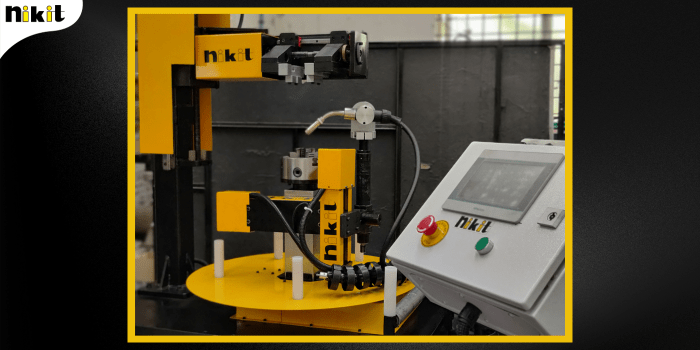

At Nikit Engineers Welding Automation & Robotics Solutions, we understand that the right welding process can significantly impact your productivity and bottom line. By selecting the appropriate orbital welding method for your specific needs, you can save time, money, and resources while achieving consistently high-quality welds.

If you’re looking to optimize your welding processes through automation and robotics, reach out to us. We’re here to provide you with practical solutions tailored to your unique requirements. Let’s work together to take your welding services to the next level.

First-Hand Experience: Free Weld Trial Services

At Nikit Engineers, we wholeheartedly embrace the notion of “Seeing to Believe.” To provide a true grasp of the transformational potential inherent in our Welding Automation & Robotics Solutions, we extend the offer of Free Weld Trial Services. This immersive, hands-on encounter equips manufacturers with the means to witness our technology’s prowess in action while evaluating its harmonization with their specific components.

During these trial sessions, the Nikit Engineers team collaborates in close tandem with our valued clients, diligently discerning their unique requirements and skillfully fashioning bespoke solutions that seamlessly align with their overarching objectives. This bespoke and client-centric approach serves to distinguish us and underlines our unwavering dedication to ensuring our clients’ utmost satisfaction.

At Nikit Engineers, we understand that each application is unique, and we work closely with our customers to develop customised welding solutions that meet their specific needs. We use the latest technology and equipment to ensure that our welding solutions are efficient, reliable, and cost-effective. We also offer training and support services to ensure that each welding process works efficiently.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineers