In the ever-evolving domain of welding automation and robotics solutions, the pursuit of heightened productivity and cost-effectiveness remains an enduring goal for businesses across diverse industries. A pivotal facet of Precision in Hydraulic Port Welding within the manufacturing sector revolves around the connectors found on pressure vessels, storage tanks, and hydraulic cylinders. For organizations seeking to optimize their welding procedures and bolster operational efficiency, Nikit Engineers Welding Automation & Robotics Solutions India has effectively addressed these challenges, as demonstrated by our comprehensive case study featuring esteemed clients such as Rane Madras, Wipro Hydraulics, Fabricators India, Preac, and Dynaforce.

Thank you for reading this post, don't forget to subscribe!Background:

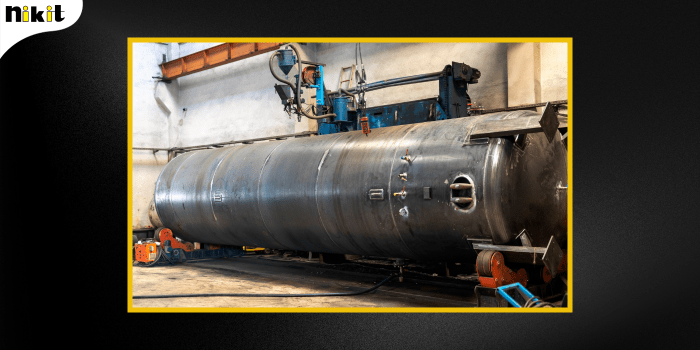

Pressure vessels, storage tanks, and hydraulic cylinders serve as indispensable components in industries such as automotive, hydraulic systems, and heavy machinery. The integrity and longevity of these components hinge on the provision of precise and enduring welding solutions.

Client Challenges:

Our clients encountered several shared challenges in hydraulic port welding, encompassing:

- Precision Demands: The necessity for precision welding loomed large to uphold the structural integrity of these critical components.

- Time Optimization: Swift turnaround times stood as a paramount requirement to meet the relentless demands of production.

- Consistency Imperative: The need for unwavering weld quality across numerous units was of utmost importance.

Our Approach to Precision in Hydraulic Port Welding:

Nikit Engineers’ cadre of welding automation specialists employed a comprehensive approach to surmount these challenges. Here is a glimpse of how we accomplished success:

Cutting-Edge Robotic Welding Technology:

We seamlessly integrated state-of-the-art robotic welding systems, meticulously tailored to the unique requisites of each client. These systems facilitated pinpoint accuracy and unwavering consistency in welding, thereby diminishing human errors and augmenting efficiency.

Bespoke Welding Protocols:

Our adept engineering team meticulously crafted customized welding programs, fine-tuning variables such as welding speed, arc length, and heat input to harmonize with the distinct demands of each project.

Stringent Quality Assurance:

We rigorously implemented quality control measures encompassing non-destructive testing and visual inspections, which were seamlessly woven into the fabric of the welding process. This ensured the perpetuation of consistently high-caliber welds.

Process Optimisation:

We fine-tuned the welding process to minimize superfluous movements and maximize speed without compromising the quality of welds.

Results for Welding Automation:

The outcomes of our hydraulic port welding ventures were nothing short of remarkable:

- Elevated Precision: Our robotic welding systems consistently delivered meticulous welds, impeccably aligning with the most exacting quality benchmarks.

- Augmented Productivity: Clients witnessed a substantial reduction in welding cycle times, thus enabling them to proficiently meet their production objectives.

- Cost-Efficiency: Decreased labor expenditures, minimal rework, and diminished material wastage contributed to cost savings for our clients.

- Quality Assurance: Our stringent quality control procedures guaranteed that each component adhered to the stipulated specifications, thereby enhancing product reliability.

Client Testimonials:

Dynaforce: “Nikit Engineers’ solutions have proven invaluable in our quest for efficiency and precision. We couldn’t be happier with the results.”

Kalki: “Nikit Engineers’ solutions have proven invaluable in our quest for efficiency and precision. We couldn’t be happier with the results.”

Conclusion:

Nikit Engineers Welding Automation & Robotics Solutions India has consistently yielded exceptional outcomes in hydraulic port welding for pressure vessels, storage tanks, and hydraulic cylinders. Our unwavering dedication to precision, efficiency, and cost-effectiveness has firmly established us as the preferred choice for industry leaders such as Rane Madras, Wipro Hydraulics, Fabricators India, Preac, and Dynaforce.

If your organization aspires to boost productivity, elevate welding quality, and trim costs, we cordially invite you to delve into our welding automation solutions. Contact us today to explore how Nikit Engineers can catalyze a transformation in your welding processes, just as we have for our esteemed clientele.

First-Hand Experience: Free Weld Trial Services

At Nikit Engineers, we adhere to the principle of “Seeing is Believing.” To genuinely grasp our Welding Automation & Robotics Solutions’ transformative potential, we extend Free Weld Trial Services. This hands-on encounter empowers manufacturers to observe our technology’s capabilities in action and assess its compatibility with their components.

Throughout these trials, the Nikit Engineers team collaborates closely with clients, comprehending their needs, and designing tailored solutions that align with their objectives. This personalised approach distinguishes us and underscores our commitment to client contentment.

In conclusion, The landscape of industrial manufacturing is evolving, and Nikit Engineers spearheads this evolution with our Welding Automation & Robotics Solutions. Through rigorous R&D Weld Trials, we showcase our dedication to innovation, precision, and efficiency. The Complimentary Weld Trial Services we provide present a unique chance for industries to embrace the future of welding firsthand. As automation gains traction across industries, the Nikit Engineers team stands prepared to revolutionise welding processes, one component at a time.

At Nikit Engineers, we understand that each application is unique, and we work closely with our customers to develop customised welding solutions that meet their specific needs. We use the latest technology and equipment to ensure that our welding solutions are efficient, reliable, and cost-effective. We also offer training and support services to ensure that each welding process works efficiently.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineers