Exploring the Benefits of Orbital Welders: Nikit Engineers’ Robotic Welding Automation Solutions in India

Discover the advantages of orbital welders and how Nikit Engineers’ cutting-edge robotic welding automation solutions are revolutionizing the welding industry in India. Experience superior precision, increased productivity, improved weld quality, enhanced safety, and cost efficiencies. Choose Nikit Engineers for your orbital welding needs.

Thank you for reading this post, don't forget to subscribe!In today’s rapidly advancing industrial landscape, technological advancements have paved the way for enhanced efficiency and precision in various manufacturing processes. Welding, a fundamental process in fabrication, has also seen significant improvements with the introduction of orbital welders. Among the leading providers of robotic welding automation solutions in India, Nikit Engineers has emerged as a reliable partner, offering cutting-edge orbital welding technology. In this blog, we will delve into the benefits of orbital welders and explore how Nikit Engineers’ solutions are transforming the welding industry in India.

1. Superior Precision and Consistency:

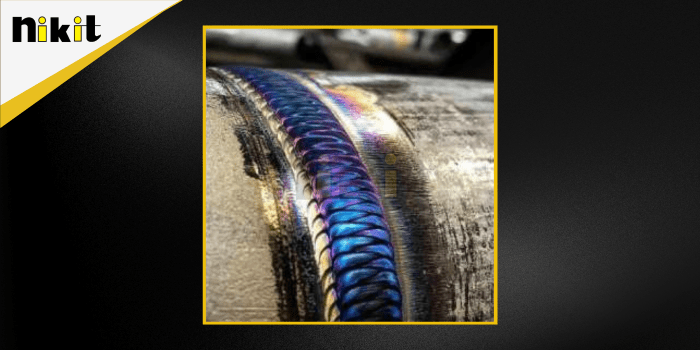

Orbital welding is known for its exceptional precision and consistency. The automated process ensures that welds are performed with utmost accuracy and repeatability. By utilizing advanced sensors and programming, orbital welders can maintain precise torch positioning, electrode arc gap, and travel speed, resulting in consistent high-quality welds. Nikit Engineers’ orbital welders are equipped with state-of-the-art control systems, guaranteeing reliable and repeatable results.

2. Increased Productivity:

Compared to traditional manual welding methods, orbital welders significantly increase productivity. These automated systems can work around the clock, reducing downtime and increasing output. By eliminating the need for manual intervention, orbital welders can complete projects faster and with greater efficiency. Nikit Engineers’ robotic welding automation solutions optimise workflow and reduce welding cycle times, ultimately boosting productivity for manufacturers.

3. Improved Weld Quality:

The precision and consistency of orbital welding translate into improved weld quality. With precise control over various welding parameters, such as travel speed, current, and arc gap, orbital welders create welds that are free from defects and inconsistencies. The automated process minimizes the risk of human error, resulting in stronger, more reliable welds. Nikit Engineers’ orbital welders adhere to international welding standards, ensuring weld quality that meets or exceeds industry requirements.

4. Enhanced Safety:

Welding is inherently hazardous, with potential risks to human operators. By integrating robotic automation, orbital welders reduce the exposure of workers to hazardous fumes, radiation, and intense heat. This not only enhances the safety of the work environment but also improves overall occupational health. Nikit Engineers’ solutions prioritize operator safety by minimising the need for manual welding and providing comprehensive safety features within their robotic welding systems.

5. Cost Efficiency with Nikit Engineers Orbital Welders:

While orbital welders require an initial investment, they offer long-term cost savings. By increasing productivity and reducing rework, these automated systems help manufacturers optimize their resources. The precise control of parameters and the elimination of human error also reduce material wastage, resulting in cost-efficient operations. Nikit Engineers’ solutions are designed to provide a rapid return on investment through improved efficiency and reduced operational costs.

Orbital welders have revolutionized the welding industry by delivering superior precision, consistency, productivity, and weld quality. Nikit Engineers, a leading provider of robotic welding automation solutions in India, offers state-of-the-art orbital welding technology. Their solutions enable manufacturers to optimize their operations, enhance safety, and achieve cost efficiencies. By embracing automation in welding processes, industries can benefit from increased productivity, improved weld quality, and a safer work environment. With Nikit Engineers’ expertise, the future of welding automation in India looks promising and poised for further advancements.

Why Choose Nikit Engineers for Your Orbital Welding Needs?

Nikit Engineers is a leading manufacturer of robotic welding machines in India. The company offers a wide range of welding solutions, including Orbital Welding, to meet the needs of manufacturers in various industries. Nikit Engineers has a team of experienced professionals who are dedicated to providing high-quality welding solutions that meet or exceed customer expectations.

At Nikit Engineers, we understand that each application is unique, and we work closely with our customers to develop customized welding solutions that meet their specific needs. We use the latest technology and equipment to ensure that our welding solutions are efficient, reliable, and cost-effective. We also offer training and support services to ensure that each welding process works efficiently.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineers