I still remember the application papers filed for my Masters in Design, completing TOEFL, SAT & even IELTS to sail through the shores for a better prospect of the west in the hope of a greater tomorrow.

Thank you for reading this post, don't forget to subscribe!Its still wake and nothing has moved so far, probably the only thing that a better tomorrow could deliver was an innovative product born purely out of survival and no business interests.

Of everything that Mr. Niranjan did for a span of 18 years was about to come a squeaking halt with the thought of selling our industry – Nikit. A slew of more than 1500 welding machines successfully running & services to comply to and an area of interest for automation, we were just about to focus more in to the welding automation domain that a great economic slow down happened. Obviously the best & the easiest way out was to put a price tag on the company and leave with paltry. On the contrary the most difficult would be to survive. We took this decision to survive & I relaxed through my admissions taking the tough path to retain the company than moving to the west. Of all the decisions I have ever taken, this was the best ever.

With scarce orders and plenty of time I decided to put forth a machine that is a combination of all the machines that my father, Mr. Niranjan had ever designed for welding automation plus the biggie would be to make such a system portable, hence i put down the design and named it “The Multi Axes System”.

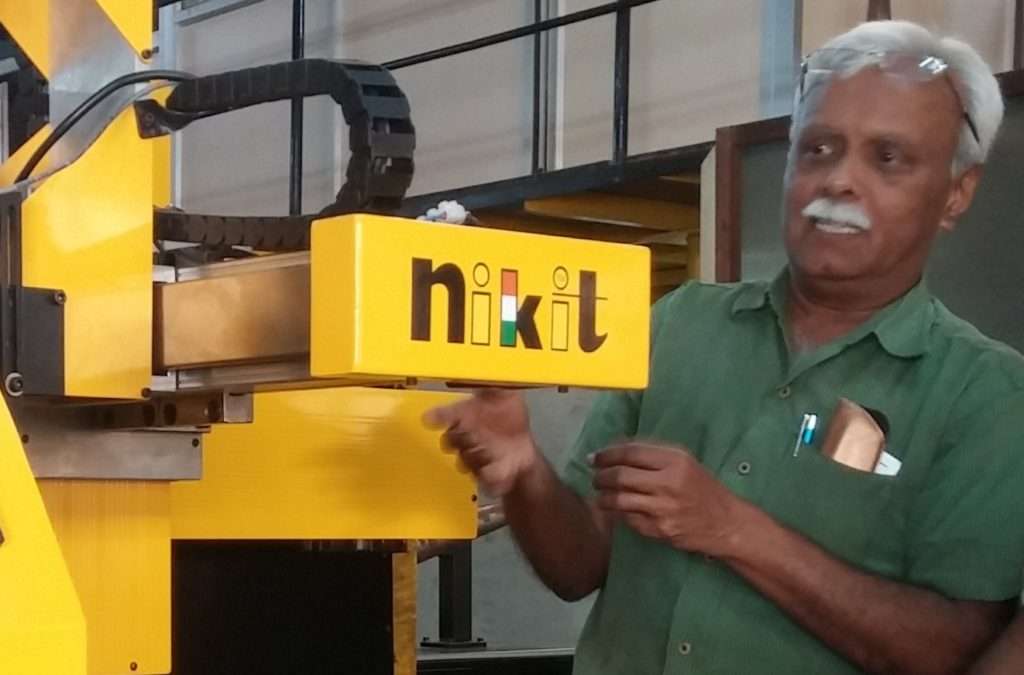

Image : “The Multi Axes System” or Portable CNC Welder

Funny enough I was too technical to not understand that the product name should be in tandem with the application it best suits for, hence declassifying it stage by stage we realized that our Multi Axes System was majorly solving one big problem. To weld Hydraulic Cylinders. Again not until we had an enquiry raised by Mr Balakrishnan from Kalki Fluid Power for a project spearheaded by Mr. Sharavanan, head of Rane Madras Hydrualic division. The requirement was such that we had to propose for one welding solution for hydraulic steering cylinder ports, one for end cap & the one more for mounting block welding. This is where the Multi Axes System a.k.a Cylinder Welder came in to actual use. Without much hesitation we proposed & presented them with our new Cylinder Welder & instead of three individual systems solving each welding issue we showcased only one machine which could weld all the three areas, round ports, end caps & mounting blocks. The concept & functionality was such that it greatly impressed the RM team and we bagged orders for two systems under the condition to deliver it within two months for the opening of their new plant in Mysore. This completely changed our

Image : Cylinder Welder V1.0

We realised the potential of such system can benefit the entire hydraulic industry as the technology of multi axes interpolation with gantry based system was not used for welding cylinders all through its components. Hence we patented the system in India & in 2016 internationally. With this we began our next journey to upgrade & release the next version which could accommodate Front End Tipper Cylinder (FET) whoch ranged up to a length of 2500mm & had multiple ports.

…….. Continued in Episode 02.