COMPONENT STUDY

Thank you for reading this post, don't forget to subscribe!THE COMPONENT IS A LAMP SHADE OUTER COVER, THE COMPONENTS ARE OF DIFFERENT SIZES AND WEIGHT FROM 1.5 Kg TO 6 Kgs AS A WHOLE .THE PICTURE SHOWS THE WELDED COMPONENT,WELD ZONES AND INDIVIDUAL COMPONENTS. (FIG 1)

COMPONENT SPECIFICATION:-

| SL NO | A/F SIZE | TYPE | WEIGTH(Kg) |

| 1 | 450 | HEXAGONAL | 1.5 |

| 2 | 600 | HEXAGONAL | 2.287 |

| 3 | 900 | HEXAGONAL | 3.540 |

| 4 | 1200 | HEXAGONAL | 4.792 |

| 5 | 1500 | HEXAGONAL | 6.044 |

THE REAL PROBLEM

1) PROFILE STITCH WELDING OF INDIVIDUAL COMPONENTS.

2) THE AUTOMATION FOR THIS WELDING AS CONTINUOUS WELDING MANUALLY WAS DIFFICULT, HAZARDOUS TO OPERATOR.

3) EASING OF OPERATION.

PROVIDING THE BEST SOLUTION

THE WELD

- THE PROFILE STITCH WELD :-

- THE WELDING IS DONE HERE TO JOIN 2 INDIVIDUAL PIECES CUT IN AN ANGLE TO ARRANGE AS A HEXAGON WHEN JOINED.

- AS THE COMPONENTS ARE WELDED USING TIG AND PARTS WERE INDIVIDUAL CUT PIECES WE HAD TO MAKE A FIXTURE IN ORDER TO ARRANGE THEM ACCURATELY.

- TIG WELDING WAS THE PROCESS USED IN ORDER TO WELD THE COMPONENT.

- IMAGES 1 AND 2 SHOWS SHOWS COMPONENT’S OUTSIDE AND ONSIDE WELDING RESPECTIVELY.

SOURCE

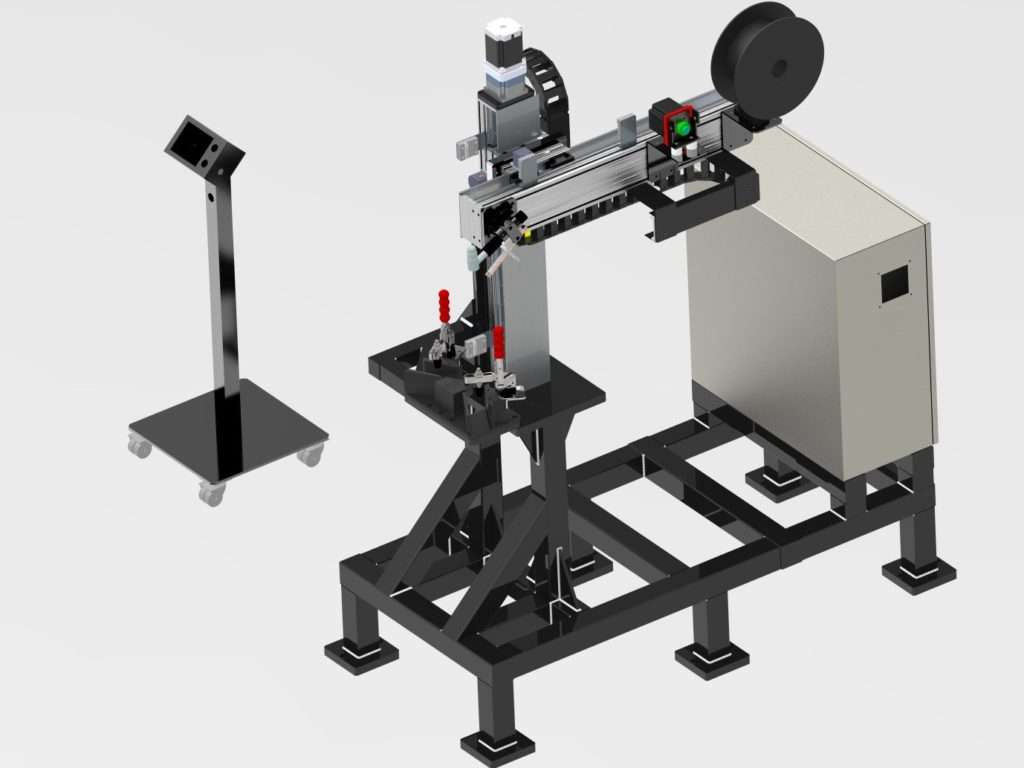

- AUTOMATION IS DONE USING 2 AXIS WELDING SPM:-

- THERE ARE 2 LINEAR AXES.

- THE TORCH IS MOVED TO THE CLOSE PROXIMITY OF THE COMPONENT IN ORDER TO CREATE WELD ARC USING 2 LINEAR AXES(Y AXIS AND Z AXIS).

- THE INDIVIDUAL COMPONENTS ARE ARRANGED USING THE FIXTURE.

- THE BELOW IMAGE SHOWS THE SPM AND AXIS USED (IMAGE 3).

- THE AUTOMATION WAS DONE IN ORDER TO DE SKILL THE PROCESS, HAVE HIGHER REPEATABILITY AND EFFICIENCY.

EASING OF OPERATION:-

- SEQUENCE OF OPERATION IS MADE ACCORDING TO CUSTOMER REQUIREMENT AND THE MACHINE IS MADE FOOL PROOF WITH COMPONENT SENSOR AND SUITABLE PROGRAM.

- FIXTURES WITH CORRECT ANGLE GROOVES WERE PROVIDED IN ORDER TO EASILY LOCATE THE INDIVIDUAL PIECES.

- IN ORDER TO ACHIEVE REPEATABILITY THE LOCATORS WERE PROVIDED IN THE FIXTURE.

- TOGGLE CLAMPS WERE USED TO CLAMP THE COMPONENTS EASILY AND EFFECTIVELY.

- IMAGE 4 SHOWS THE FIXTURE ARRANGEMENT AND LOCATOR INCLUDED AND IT’S TOGGLE CLAMP.

GOALS ACHIEVED

- AFTER CAREFULLY WORKING ON CUSTOMER REQUIREMENTS WE DELIVERED AN SPM WHICH NOT ONLY SATISFIED THE CUSTOMER BUT MADE THE CUSTOMER HAPPY.

- THE MACHINE IS NOW PRODUCING 40 SUCH WELDED COMPONENTS IN A SHIFT WITH THE CUSTOMER WORKING FOR 3 SHIFTS PER DAY.

- AN OPERATOR WHO DOESN’T KNOW WELDING CAN ALSO OPERATE THE MACHINE, IT HAS HELPED IN DE-SKILLING OF PROCESS.

- THE COMPONENTS CAN BE EASILY LOCATED AND HENCE SIMPLIFYING THE WORK.

- THE OPERATOR IS NOT UNDER INFLUENCE OF HARMFUL GASES HENCE IT SAFE GUARDS THE OPERATOR.